Expert Advice on Maintaining Peak Performance via strapping machine service

The Relevance of Regular Strapping Machine Service for Smooth and Reliable Packaging Processes

Regular strapping machine service plays a necessary function in guaranteeing reliable packaging procedures. Disregarding upkeep can lead to unanticipated break downs and decreased performance. By proactively dealing with possible concerns, businesses can enhance both machine efficiency and product quality. Understanding the relevance of normal service is fundamental for preserving operational performance. Nevertheless, several companies forget this essential aspect. What variables should be thought about to develop a reliable maintenance technique?

Comprehending Strapping Machines and Their Duty in Product packaging

Although strapping machines may appear like basic devices, they play an essential duty in the product packaging sector by ensuring the protected packing of items. These machines apply plastic or steel straps around packages, offering stability throughout transportation and storage space. By developing limited, trusted seals, strapping machines aid protect against damages and keep product integrity. Their performance adds to quicker packaging processes, permitting services to meet boosting need without compromising top quality. Additionally, strapping machines can be integrated into automated systems, boosting operations and decreasing labor expenses. The convenience of these machines makes them ideal for different sectors, from making to circulation, making sure that items stay undamaged throughout the supply chain. Ultimately, strapping machines are vital to effective product packaging operations.

Typical Problems Developing From Absence of Upkeep

When strapping machines are not appropriately kept, several typical problems can arise that impede their efficiency and dependability. Constant malfunctions can happen because of worn-out parts, bring about expensive downtimes and interfered with production timetables. Additionally, incorrect tensioning might result in weak seals, jeopardizing package stability. Dust and debris buildup can harm machine sensors and relocating components, creating unpredictable operation and boosted wear. Moreover, overlooked lubrication can cause friction and getting too hot, further destructive internal mechanisms. Operators might also face difficulties when readjusting settings on inadequately maintained machines, leading to irregular packaging results - strapping machine service. On the whole, a lack of upkeep can seriously influence the performance and efficiency of strapping machines, eventually influencing the entire product packaging procedure

Advantages of Routine Strapping Machine Service

Normal strapping machine service supplies substantial advantages that add to operational success. By guaranteeing boosted tools longevity and enhanced operational effectiveness, companies can decrease the chance of unanticipated break downs. Ultimately, this aggressive strategy reduces downtime dangers, fostering a much more trusted manufacturing atmosphere.

Enhanced Tools Durability

Maintaining a strapping machine with regular service greatly adds to its total longevity. Routine inspections and maintenance help determine wear and tear before they escalate right into significant concerns, therefore extending the life of critical parts. By resolving minor mistakes immediately, drivers can prevent costly repairs and substantial downtime that can occur from overlook. In addition, regular servicing assurances that all mechanical parts function properly, minimizing the risk of machine failing during procedures. This positive strategy not just improves the strapping machine's resilience however additionally promotes a much safer working environment. Eventually, buying routine service translates to an extra reputable machine that consistently satisfies production demands, securing the integrity of the packaging procedure for several years ahead.

Boosted Functional Effectiveness

Regular service of strapping machines significantly enhances operational effectiveness by ensuring that all parts function at their ideal. Routine upkeep decreases the risk of mechanical failings, permitting reputable and regular performance. Well-maintained machines run at optimal rates, making best use of throughput and reducing the moment required for product packaging procedures. This performance not just aids fulfill manufacturing targets however also contributes to a smoother operations, as operators can count on the devices without disruptions. In addition, routine maintenance identifies potential problems early, permitting for corrective activities to be taken before they rise. Because of this, businesses experience streamlined procedures, which can result in boosted performance and boosted total efficiency in product packaging jobs. Normal service is crucial for keeping a reliable product packaging setting.

Lowered Downtime Risks

Reliable service schedules for strapping machines significantly reduce the risks of downtime connected with unforeseen mechanical failures. Routine maintenance checks help determine prospective problems before they escalate, guaranteeing that machines run efficiently and reliably. By addressing damage, lubrication needs, and electrical elements proactively, businesses can prevent expensive disruptions in their product packaging procedures. Additionally, set up servicing enhances the life expectancy of strapping machines, reducing the regularity of replacements and linked costs. The decrease in unintended downtime not only enhances productivity yet also boosts staff member morale, as employees can count on equipment that operates perfectly. Inevitably, committing to regular service builds a resilient procedure, guarding against disturbances and allowing firms to satisfy production targets continually.

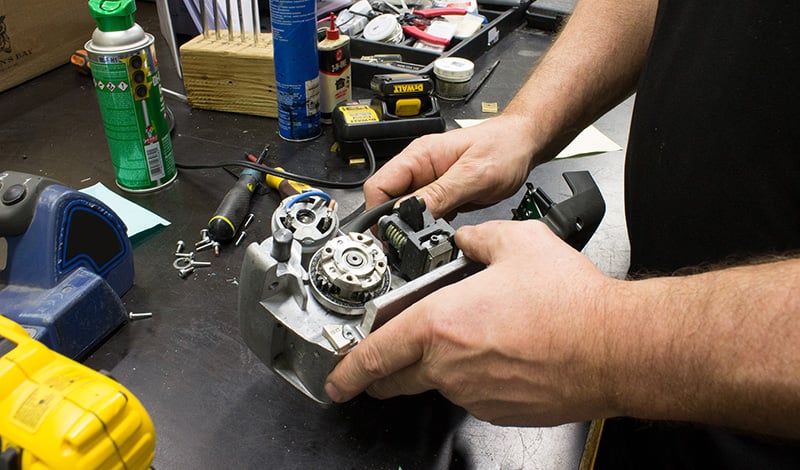

Key Components to Screen During Routine Service

While executing regular service on a strapping machine, it is crucial to monitor several vital elements to secure peak efficiency and long life. The tensioning mechanism must be checked for proper operation, assuring that straps are firmly tightened without causing damages. The sealing system must be examined for deterioration, as any type of breakdown can compromise the stability of the product packaging. In addition, the feed system calls for attention to ensure smooth and consistent strap delivery. It is likewise important to examine electrical connections, as broken or loosened circuitry can result in functional failings. Lastly, lubrication this levels must be examined to stop friction-related problems, advertising reliable machine function. On a regular basis checking these parts will certainly contribute greatly to the machine's general dependability.

Developing a Maintenance Schedule

A well-designed upkeep schedule plays a critical role in making sure the suitable procedure of a strapping machine. It ought to include regular assessments, cleansing, and component replacements based on the manufacturer's suggestions. Developing a regularity for these jobs-- such as weekly, month-to-month, or quarterly-- can aid preemptively address prospective concerns. In addition, documenting each maintenance activity boosts liability and permits tracking the machine's efficiency gradually. Operators ought to also take into consideration the manufacturing volume and certain functional demands when customizing the schedule. By focusing on regular service, services can minimize downtime, prolong the machine's life expectancy, and maintain regular product packaging quality. Ultimately, a complete upkeep schedule is vital for optimizing strapping machine functionality and reliability in product packaging procedures.

Picking the Right Service Provider

Exactly how can one assure the choice of a suitable service providerfor strapping machine upkeep? It is vital to research study possible companies extensively. Examining their experience, sector online reputation, and competence in strapping machine modern technologies can provide useful insights. In addition, client reviews and testimonials commonly expose the quality of service and integrity.

Next off, think about the supplier's certification and training programs, which show their dedication to preserving high requirements. It is also essential to inquire about their response times for service calls and the accessibility of extra components.

Lastly, obtaining multiple quotes enables a comparison of rates and service plans, guaranteeing an educated choice. Inevitably, the right provider will enhance efficiency and lower downtime in product packaging procedures.

The Long-Term Influence of Constant Machine Care

Consistent machine care considerably affects the long life and efficiency of strapping machines, as routine maintenance helps recognize prospective concerns before they intensify. By carrying out an organized service timetable, businesses can decrease costly repairs and unexpected downtimes. This proactive strategy not just assures peak functioning but also improves the quality of product packaging, leading to improved client satisfaction. Gradually, well-kept machines show far better performance, resulting in lowered operational costs find more information and enhanced performance. Additionally, a society of routine treatment fosters employee confidence in equipment dependability, promoting a smoother process. Ultimately, the long-term impact of consistent machine treatment converts into considerable savings and a competitive edge in the packaging industry, making it a crucial method for companies looking for lasting growth.

Often Asked Questions

Exactly how Often Should I Replace Strapping Machine Parts?

Strapping machine parts must be changed every 1,000 to 2,000 hours of procedure, depending upon usage strength. strapping machine service. Normal evaluations can help establish details needs, guaranteeing peak efficiency and reducing downtime from equipment failing

Can I Execute Upkeep on My Own?

Yes, one can perform upkeep on their very own, offered they have the required skills and understanding. Getting in touch with the maker's standards is vital to guarantee appropriate procedures are adhered to and safety and security is maintained.

What Indications Show I Need Immediate Service?

Indicators indicating the demand for immediate service consist of unusual sounds, inconsistent strapping stress, constant mistake messages, visible endure components, or unexpected closures (strapping machine service). Addressing these issues quickly assures functional effectiveness and protects against more damages

Exactly How Does Weather Condition Affect Strapping Machine Performance?

Climate conditions can significantly impact that site strapping machine performance. Extreme temperatures, humidity, and dampness levels may trigger materials to expand or contract, affecting tension and seal honesty, resulting in potential operational concerns and decreased packaging effectiveness.

What Is the Average Expense of Regimen Service?

The ordinary cost of regular service for strapping machines generally varies from $150 to $500, depending upon the machine's complexity and the company's knowledge, making certain peak efficiency and durability of the tools.

Routine strapping machine service plays a crucial duty in making certain reliable packaging procedures. Routine service of strapping machines greatly enhances operational performance by making sure that all elements function at their best. While doing routine service on a strapping machine, it is important to keep an eye on numerous key elements to secure peak performance and longevity. By prioritizing regular service, businesses can lessen downtime, prolong the machine's life-span, and preserve constant product packaging quality. Consistent machine treatment substantially influences the longevity and efficiency of strapping machines, as routine upkeep helps identify prospective issues before they escalate.